Previous Projects

How much does it cost to restore a Jaguar E-Type?

An E-Type is a great average when it comes to restoring a classic car. They have a complex drive train, suspension and body fit. However parts are plentiful and there are a number of specialist suppliers allowing for a competitive spares market. We have completed at least one E-Type every year for the last 7 years and these calculations form the back bone of every quote we do.

Obviously not every car needs everything doing to it. Some may come with an interior that is all in good condition, and engine, gearbox or rear cradle that has been recently refurbished or the body may be completely rust free. But if you are buying a ‘barn find’ that has not turned a wheel in 30 years this is the commitment you are making:

Labour to disassemble, assess and clean

140 hours

Probably the most important stage of any restoration. As each component comes off the vehicle it must be photographed and assessed. If it can be reused it needs to be cleaned, either by a chemical bath, bead blasting or carefully by hand. Once this has been done a schedule can then be put together which makes sure that when the car is ready to be re-assembled:

- We know how it goes back together

- The parts have been refurbished or replaced with new

- The integrity of the original car is maintained

Bodywork

100 hours

Most ‘repairs’ to a body shell can be dealt with in 100 hours. These might include:

- Reshaping panels with dents

- Some rust repairs to jacking points, bottoms of doors, sill sections etc

- Removing original paint/under seal + Zinc prime

- Chassis/outrigger repair

However it is not going to rebuild a badly damaged or rusted out body shell. Metal work is highly skilled and takes time so assessing the body is of utmost importance before any budget can be agreed.

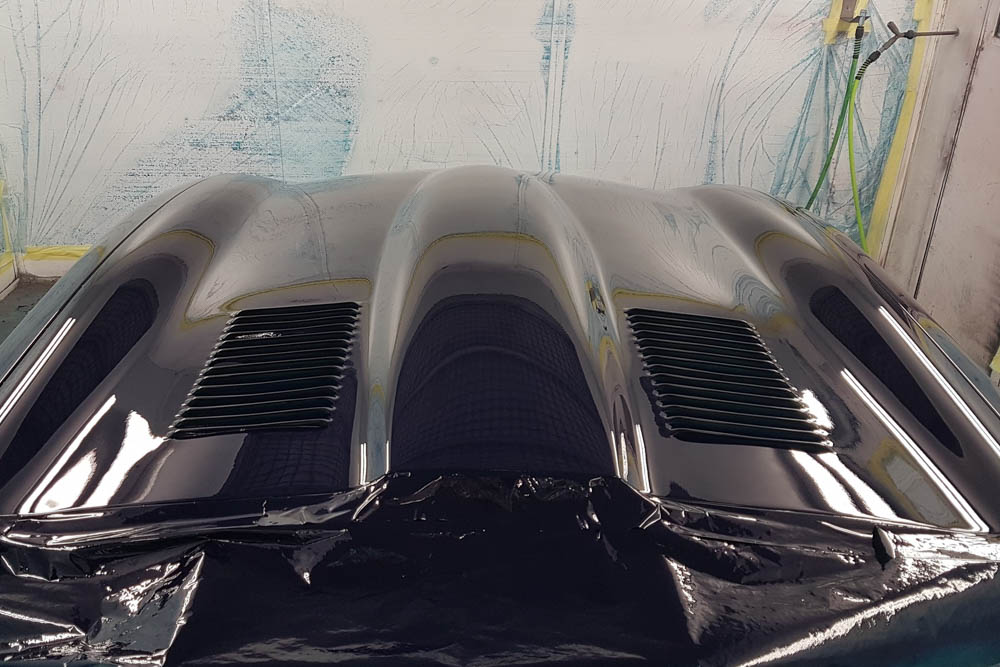

Paintwork

160 hours

Once a body shell has had its paint, under seal and any rust removed plus any fabrication carried out it can be prepared and painted. The body will be dry built, shaped and once we are happy:

- Zinc Primed – for corrosion protection

- Undersealed with (Colour matched) 2-Pack Raptor Coat on the underside (crinkle finish), inside and engine bay (smooth finish). This tough paint gives exceptional coverage and chemical/rust protection

- Painted in your choice of colour

- Lacquered to seal the paint and give a deep glossy finish.

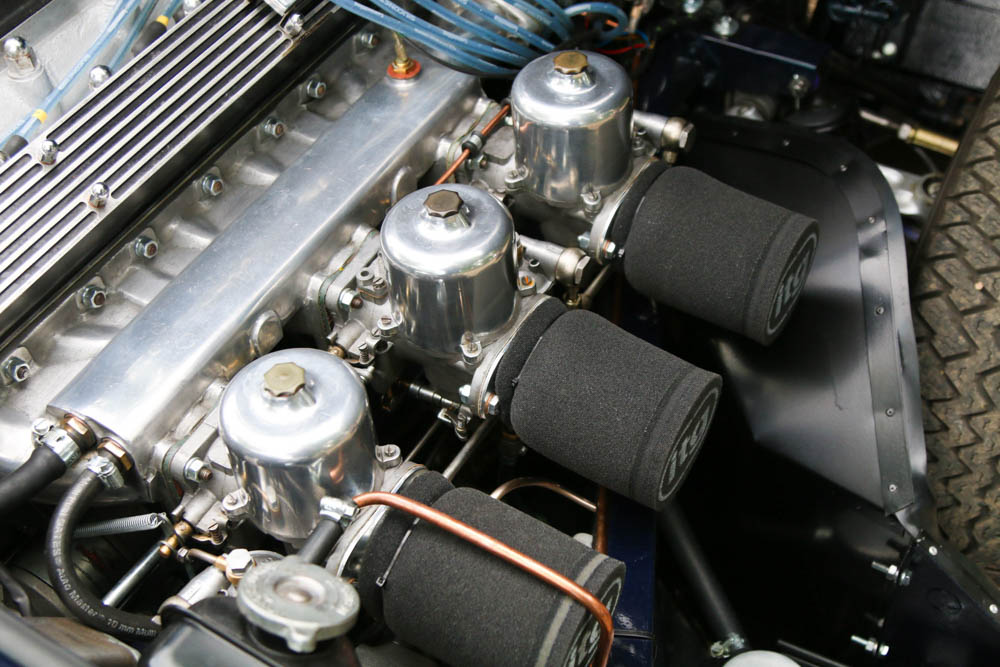

Major Component Refurbishment

£8,500 + VAT

Major components include: The engine, gearbox, axle and in the case of an E-Type the rear sub frame or cradle. Generally not all of these will need a complete rebuild we can check their health and decide which need some love and attention.

Secondary Component Refurbishment

£5,530 + VAT

These include suspension components, gauges, heater boxes, steering wheels, road wheels, steering racks/columns, hubs, brake calipers, fuel tanks etc.

Parts and consumables

£12,500 + VAT

This is where our detailed list from the strip process becomes really important. By knowing what we need to replace right at the beginning we can make sure that the parts are sourced and ordered in the most cost effective way possible. They will include:

- Rubber components such as seals, mounts and bushes

- Shock absorbers/springs

- Radiator, water pump, header tank etc

- Upgrades to electric fan, high torque starter motor, electronic ignition

- New fastenings, nuts, bolts, washers

- Brake discs, caliper rebuild kits, pads etc

- Chrome and bright work replacement/refurbishment

- Service parts and fluids

- New wiring loom and associated components

Interior Re-trim

£8,000 + VAT

A complete interior in the material of your choice includes:

- Carpet set

- Headlining

- Re-upholster of seats including covers, foams and base overhaul

- Dash repairs and re-trims

- Door cards

- Replacement vinyl/leather trims

Labour to rebuild and test

500 hours

Faced with a jigsaw puzzle of new/refurbished components, sub frames and chassis/body shell the rebuild can commence. We use a dedicated two man team to complete every build. They will have:

- Stripped the vehicle

- Know where every component is

- Have all the manufacturer specs and handbooks available

- Have a huge record of pictures to help them put it back together exactly as it should be.

We budget 400 hours for the initial build and a further 100 hours for tuning, set up, MOT and shake down. The engineers and management will complete 250 miles before the car is professionally machine polished, detailed and ready to be handed over.