Caring for Classics, Maintenance, Products

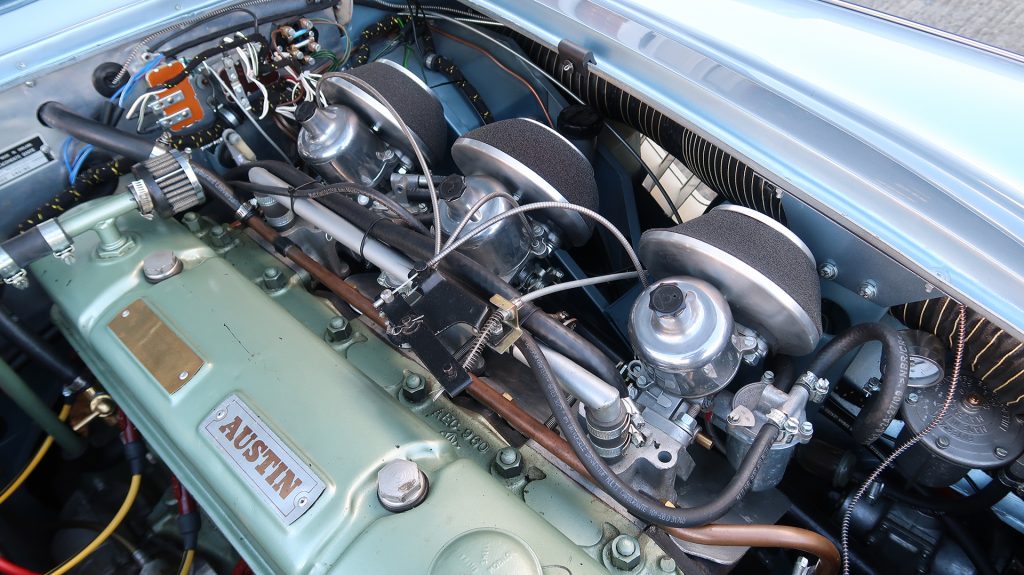

Engine Rebuilds

When should you consider having an engine rebuilt?

Major heart surgery is something to be avoided if at all possible, but, engines are mechanical components and they do wear out and they suffer from poor maintenance. The first nugget of advice is: If you are concerned about the health of your engine then get it checked out as early as possible. Very often issues such as low oil pressure can be solved without a total rebuild.

How do you check if an engine is healthy?

We often speak to people who are convinced that their engine needs a rebuild, when usually a good service, carb rebuild or ignition set up brings it right back to life. We see about 6 instances a year where a total rebuild is necessary. To put that in perspective, that is less than 3% of all the cars that arrive at Project Shop. When you start talking about engine health, there are some tests you can do to give a very clear indication of its condition before a strip down. These are:

Sniff Test

Rather a terrible name, but basically you are checking for exhaust fumes in the coolant. A positive test would suggest that you have a head gasket issue as exhaust gasses are leaking into the cooling system via the waterways that run between the engine block and head.

Compression Test

This is where you use a pressure gauge to measure how well the piston is compressing the fuel/air mixture in each cylinder. On worn out engines this pressure escapes, either round the piston, past the valves or between the joining surface between the head and the block. A rough rule of thumb is that road engines should have over 150 ft/lb of pressure when in fine fettle. Above 125 ft/lb is acceptable, but if it is close to 100 ft/lb it is pretty worn and anything less you are in trouble.

Leakdown Test

This is where you check where this pressure may be leaking from. If the pressure is leaking from the valves, the clearances may just need adjusting, if it is from the head then your engine will need a ‘top end build’ and if it is from the rings then you’re going to be into a rebore and pistons too.

Oil Pressure

Consistent oil pressure across a wide range of engine speeds and temperatures is paramount. Without a good slug of oil going round your engine components will get hot and wear out! As a rough rule of thumb most classic cars oil pressure will fluctuate between 20 PSI when hot and on tick over to 80 PSi when either cold or under load. Low oil pressure can be a multitude of sins, gummed up oil galleries, clogged up sump, crank wear, incorrect oil, the list goes on, but if you have any issues get it looked at quickly!

What can Project Shop can do to help?

We have specialist equipment that can carry out all of these tests in a couple of hours. From there we can advise you of the best course of action. We rebuild a lot of engines in house, with machine work carried out by our partners, but we also have some amazing contacts with specialist rebuild companies we can put you in touch with if you want something more bespoke.